N42 Neodymium Fishing Pot Magnet with M10 Eyebolt and Rope

Free Samples N35 N38 N40 N42 N45 N48 N50 N52 Strong Neodymium MagnetOne-Stop Service ,Total Magnetic SolutionProducts DescriptionNeodymium Pot magnetThe magnetic force of pot magnets is very strong , so they are widely used for heavy handling duties,...

- Overview

- Related Products

Free Samples N35 N38 N40 N42 N45 N48 N50 N52 Strong Neodymium Magnet

One-Stop Service ,Total Magnetic Solution

Products Description

Neodymium Pot magnet

The magnetic force of pot magnets is very strong , so they are widely used for heavy handling duties, it is quite safe due to it is permanently magnetic, a complete of series with different fixing methods and sizes are available, you can easily find the way to fix them, due to these conveniences, it greatly broadens the applications of pot magnets both in commercial and industrial, like industrial working room, office, store and home.

Feature

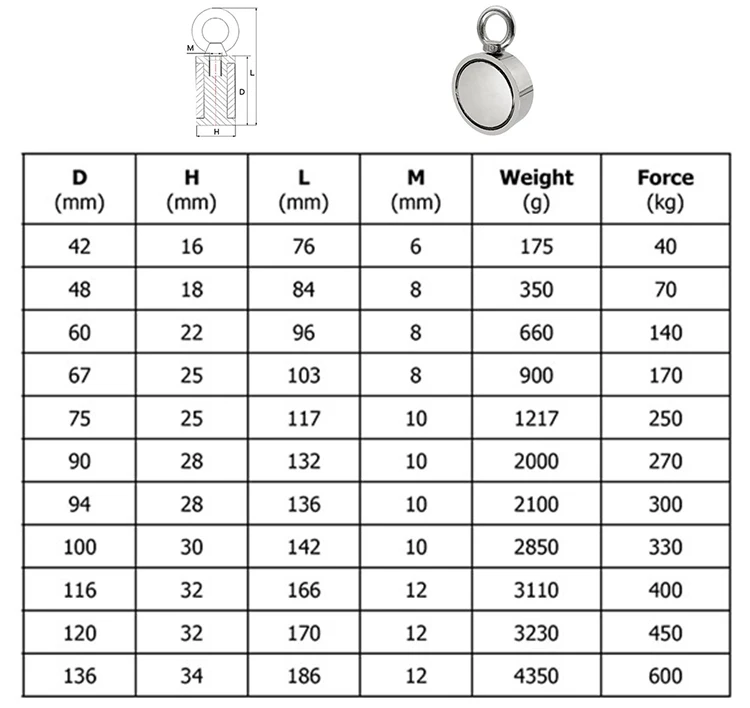

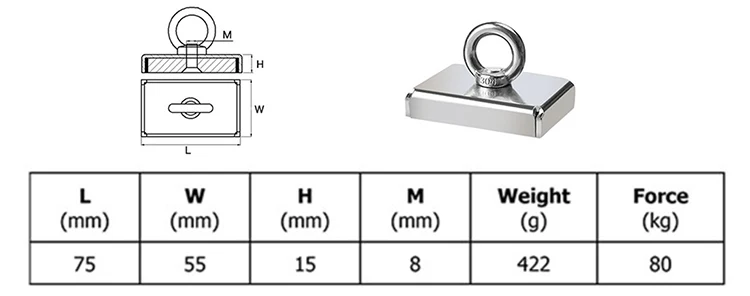

1. Part Name: D74mm Neodymium Fishing /Searching Magnet with 10 meters rope

2. Material: Neodymium Magnet N42+A3 steel+Black Resin

3. Size:D74mm(Diameter)*28mm(magnetic base height )

4. Vertical Pull-force: 300KG of each Side (Two Sides of Magnetic Attracting Force surface )

5. Max Working Tempearture:80 degrees

Warnings:

1. Strong Magnet could pinch your finger badly;

2. Keep strong magnet away from Children;

3. Do not allow magnets to attach together (especially naked neodymium magnet), any cracks and chips could hurt your eyes.

2. Material: Neodymium Magnet N42+A3 steel+Black Resin

3. Size:D74mm(Diameter)*28mm(magnetic base height )

4. Vertical Pull-force: 300KG of each Side (Two Sides of Magnetic Attracting Force surface )

5. Max Working Tempearture:80 degrees

Warnings:

1. Strong Magnet could pinch your finger badly;

2. Keep strong magnet away from Children;

3. Do not allow magnets to attach together (especially naked neodymium magnet), any cracks and chips could hurt your eyes.

Item Name |

Fishing Pot magnet |

||||||

Material |

Neodymium Iron Boron |

||||||

Grade |

Custom made N28 to N54 (NM-EH ) |

||||||

Size |

Customers' Request |

||||||

Coating |

Nickel-plated (Ni-Cu-Ni-Au),Zn,Expoy,Sliver,others |

||||||

Magnetization |

Thickness, Axial(Other Magnetism direction Contact us) |

||||||

Sample Time |

1-5 Days |

||||||

Leading Time |

8-25 days |

||||||

Generally the NdFeB/Neodymium magnets are axially and diametrically magnetized.

The axially neodymium magnet is means one circular flat face is a North pole, the other circular flat face is a South pole with the distance between the flat faces (the disc thickness) being the distance between the poles (the magnet is magnetized along the central axis of the Neodymium disc magnet). Almost all our NdFeB/Neodymium magnets are supplied as axially magnetized NdFeB magnets.

According to customized request, neodymium magnet can make to different shape/different size. Neodymium magnets or NdFeB disc magnets are round coin-shaped Neodymium magnets of varying diameter and thickness.

Disc Magnet

Block Magnet

Countersunk Magnet

Ring Magnet

Arc Magnet

Custom Magnet

Plating and Coating

Coating: Nickel-Copper-Nickel

Coating: Chrome(Cr)

Coating: Zinc

Coating: Black Epoxy

Coating: Gold

Coating: Rubber

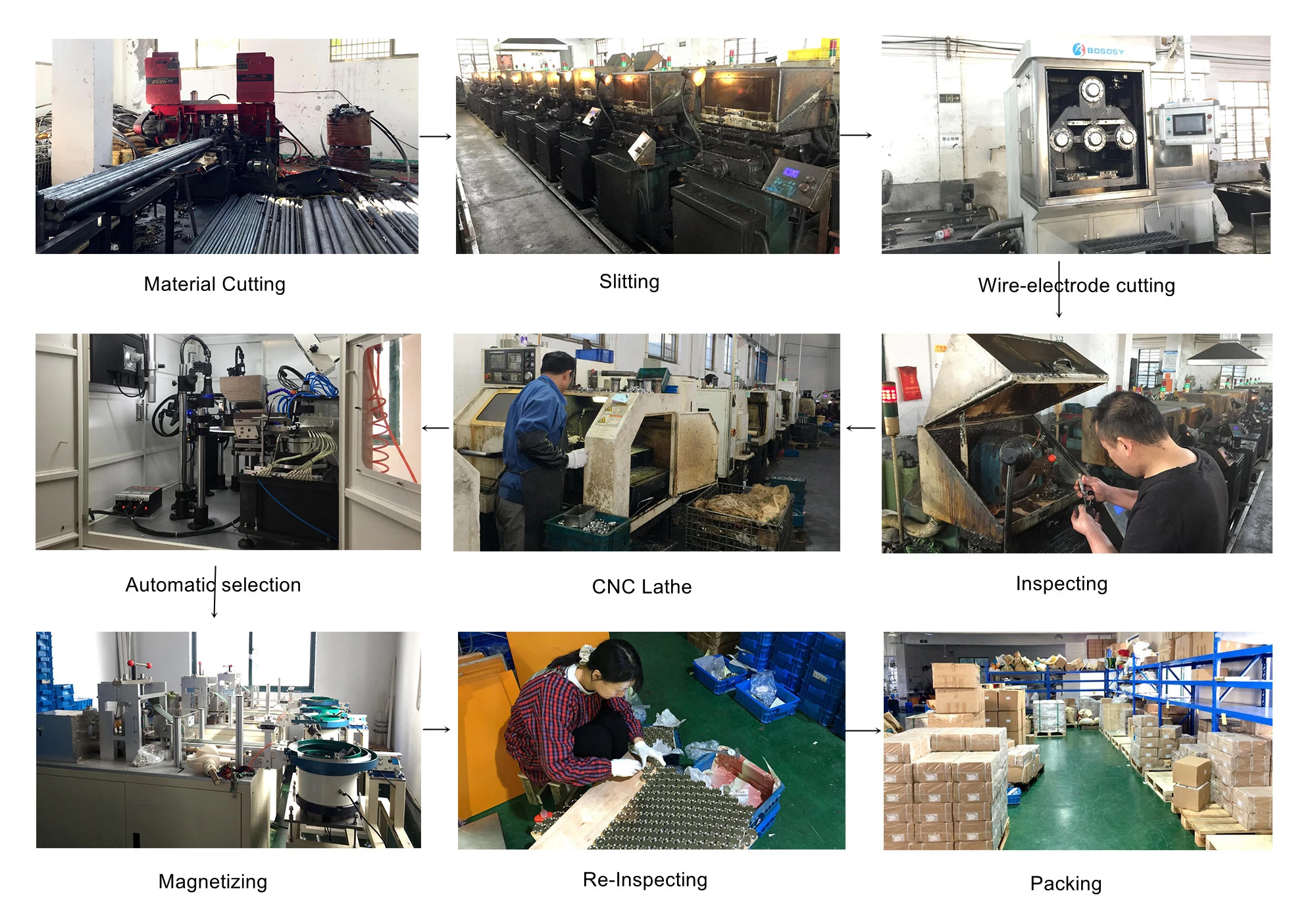

Packing & Delivery

Company Profile

Ningbo Ketai Magnetic Material Co., Ltd

NO.28 Tongsheng, Lane, Yinzhou District, Ningbo 315105 China

Tel:0086-574-55221687

Fax:0086-574-55221686

Mobile:0086-13645847550

Website: www.ketaimagnets.com/www.ketai-magnets.com

Ningbo Ketai Magnetic Material Co., Ltd. is a manufacturer of NdFeB magnets and magnetic products with well-equipped testing equipment and strong technical force.Our main products are neodymium magnets, alnico magnets, smco magnets, ferrite magnets,flexible magnets and magnetic products.With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in the fields of motor, communication, medical treatment, electronic instrument, magnetic separator, aerospace and daily necessity and other industries.Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs.We always insist on the business concept of "Customer First, Product Quality Is Corporate Life". Customers' demand is just our pursuit. We are willing to develop with domestic and foreign customers for a brilliant future!

FAQ

Q: May we get a sample of the product? How to ship and how to pay ?

A: Yes,the samples testing should be necessary for first time , we would like cooperate for samples. If it's regular magnets and we have stock , we would like supply free samples for customers, if need new production , we will quote samples fee and we can accept T/T, Paypal , Western Union , Alibaba trade assurance for payment.We will send the sample to you by DHL express.

Q: What magnet materials are available?

A: There are many different magnet materials available, which we are able to provide. These include neodymium, samarium cobalt,alnico, ferrite, bonded neodymium, bonded samarium cobalt, bonded ferrite, injection molded neodymium, injection molded samarium cobalt, rubber stripping, and FeCrCu. If there is another material you wish to procure, please contact us.

Q:Can you supply custom magnets?

A: Yes, we have the capability to produce magnets to your specification in NdFeB, SmCo, AlNiCo, Ferrite, and rubberized magnet materials. You can contact us for more details .

Q:Do you have a minimum purchase order?

A: The manufacturing of magnets is a complex process, please check our production flow for more information. As considering the production time and cost, we suggest the batch order value should be more than US$3000 per time; Of course, if less than US$3000,we also would like quote our offer for your kind consideration, so we have no strict MOQ .

Q: How many days does it take to ship my order?

A: In generally, the sintering NdFeB and SmCo magnet production time is 15-25days, cast AlNiCo will take 25-30days , the magnetic assemblies will be about 30-40 days for your reference , the exact time need to be checked before the order .

Q:What elements affect the magnet price ?

A: 1. Shape and size : cylinder (DxH), cuboids(LxWxH) ,cubes, ring(ODxIDxH) belong to regular shape , arc magnets are popular used in motors or generators , before quotation and batch production , we have to confirm the technical drawing and samples, other irregular shape magnets are also can be made according to request.

2: Grade (Magnetic Property)

3: Plating(Coating)

4:Magnetizing Orientation

5:Quantity

A: Yes,the samples testing should be necessary for first time , we would like cooperate for samples. If it's regular magnets and we have stock , we would like supply free samples for customers, if need new production , we will quote samples fee and we can accept T/T, Paypal , Western Union , Alibaba trade assurance for payment.We will send the sample to you by DHL express.

Q: What magnet materials are available?

A: There are many different magnet materials available, which we are able to provide. These include neodymium, samarium cobalt,alnico, ferrite, bonded neodymium, bonded samarium cobalt, bonded ferrite, injection molded neodymium, injection molded samarium cobalt, rubber stripping, and FeCrCu. If there is another material you wish to procure, please contact us.

Q:Can you supply custom magnets?

A: Yes, we have the capability to produce magnets to your specification in NdFeB, SmCo, AlNiCo, Ferrite, and rubberized magnet materials. You can contact us for more details .

Q:Do you have a minimum purchase order?

A: The manufacturing of magnets is a complex process, please check our production flow for more information. As considering the production time and cost, we suggest the batch order value should be more than US$3000 per time; Of course, if less than US$3000,we also would like quote our offer for your kind consideration, so we have no strict MOQ .

Q: How many days does it take to ship my order?

A: In generally, the sintering NdFeB and SmCo magnet production time is 15-25days, cast AlNiCo will take 25-30days , the magnetic assemblies will be about 30-40 days for your reference , the exact time need to be checked before the order .

Q:What elements affect the magnet price ?

A: 1. Shape and size : cylinder (DxH), cuboids(LxWxH) ,cubes, ring(ODxIDxH) belong to regular shape , arc magnets are popular used in motors or generators , before quotation and batch production , we have to confirm the technical drawing and samples, other irregular shape magnets are also can be made according to request.

2: Grade (Magnetic Property)

3: Plating(Coating)

4:Magnetizing Orientation

5:Quantity

Contact Information