Sintered N35-N52 Disc Countersunk Hole Neodymium Magnet NiCuNi Coating

- Overview

- Related Products

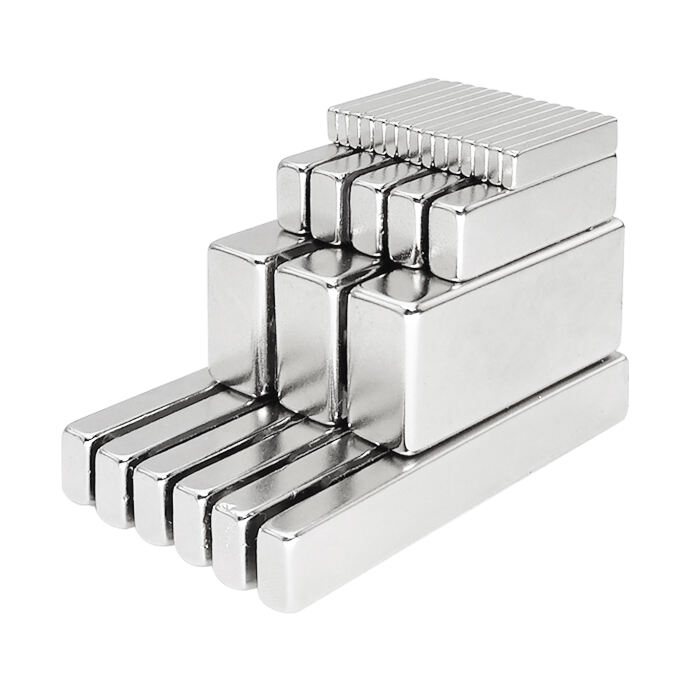

Introducing, the Ketaimag’s Sintered N35-N52 Disc Countersunk Hole Neodymium Magnet with NiCuNi Coating, perfect for all your magnetic needs. Whether you're a DIY enthusiast or a professional, these strong and durable magnets will be a valuable addition to your toolkit.

Made from high-quality neodymium material, these magnets are available in various grades (N35-N52) to suit different applications. The disc shape with countersunk hole design allows for easy mounting and installation, making them versatile for a wide range of projects. The NiCuNi coating provides a sleek and smooth finish that not only protects the magnet from corrosion but also enhances its longevity.

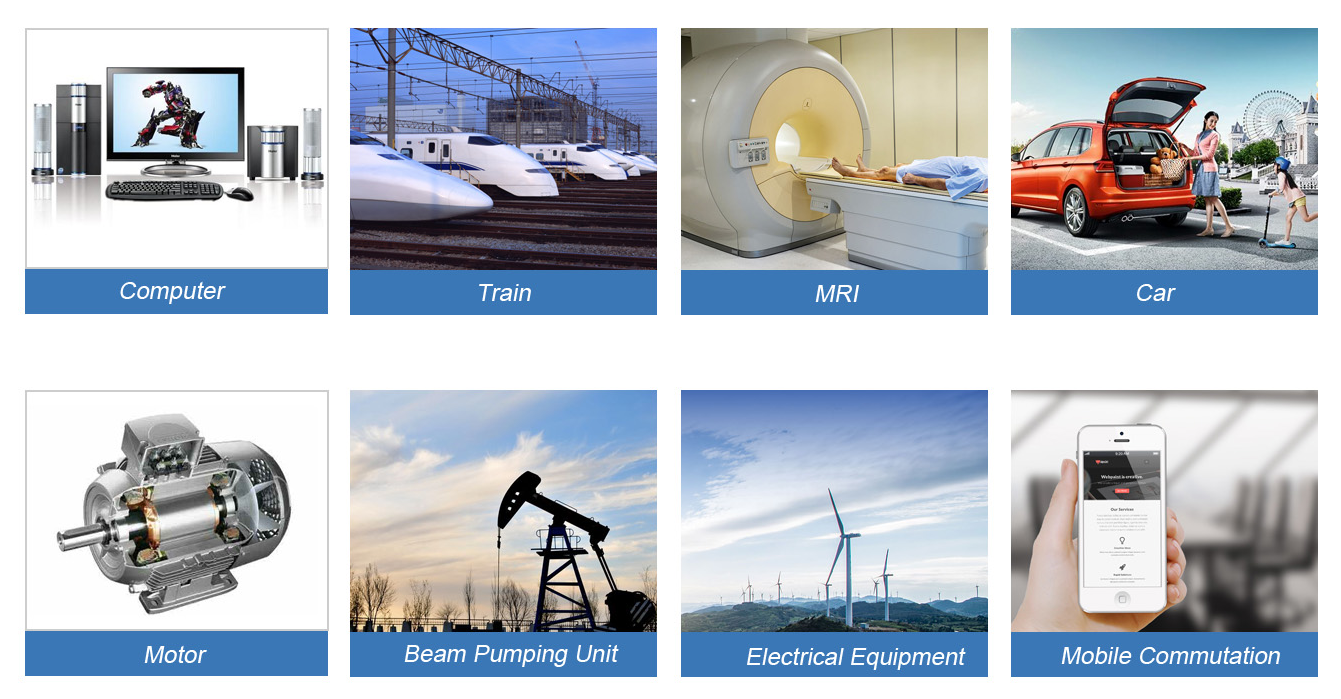

These neodymium magnets are known for their exceptional strength and magnetic properties, making them ideal for a wide range of industrial, commercial, and personal uses. From securing signage and displays to organizing tools and inventory, these magnets can handle it all with ease. Their compact size and impressive holding power make them a must-have for various applications.

The Ketaimag’s Sintered N35-N52 Disc Countersunk Hole Neodymium Magnet with NiCuNi Coating is designed to meet the highest standards of quality and performance. Each magnet is carefully crafted to ensure consistent magnetic strength and durability, so you can rely on them for years to come. Whether you're using them for woodworking, crafting, or scientific experiments, these magnets will exceed your expectations.

When it comes to safety, these magnets are built to withstand tough conditions and heavy-duty use. The countersunk hole design allows you to securely mount the magnet without compromising its strength or integrity. Additionally, the NiCuNi coating provides an extra layer of protection against wear and tear, ensuring that the magnet remains in top condition even after repeated use.

The Ketaimag’s Sintered N35-N52 Disc Countersunk Hole Neodymium Magnet with NiCuNi Coating is a high-quality, reliable, and versatile product that will enhance your projects and applications. With their strong magnetic properties, durable construction, and convenient design, these magnets are a valuable addition to any toolbox. Experience the power of neodymium magnets with Ketaimag today

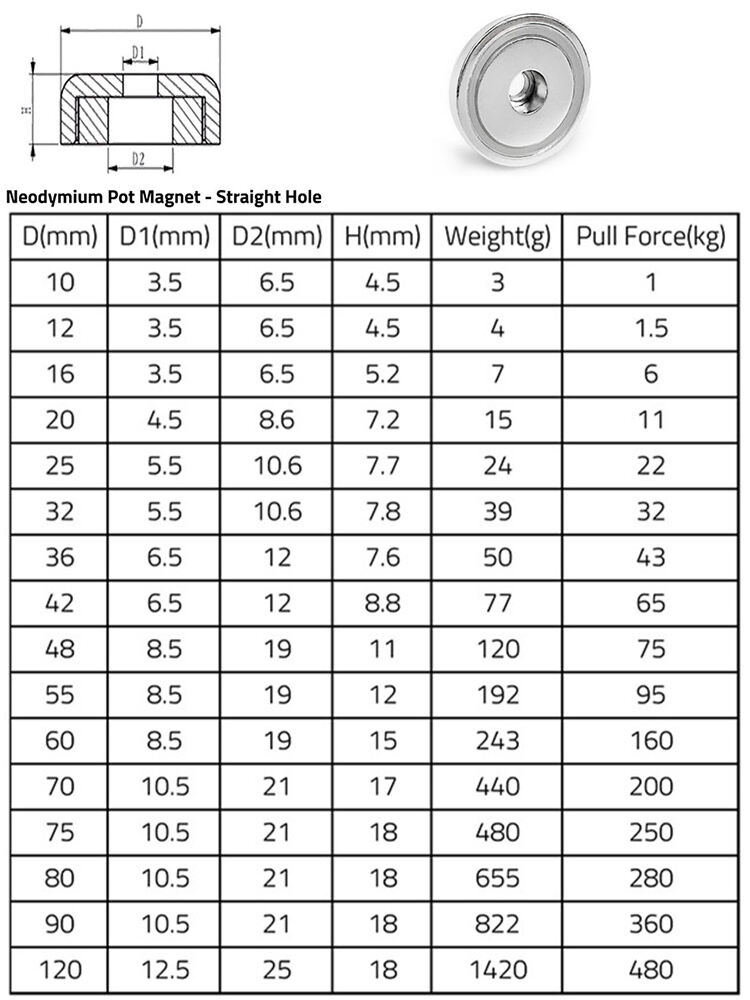

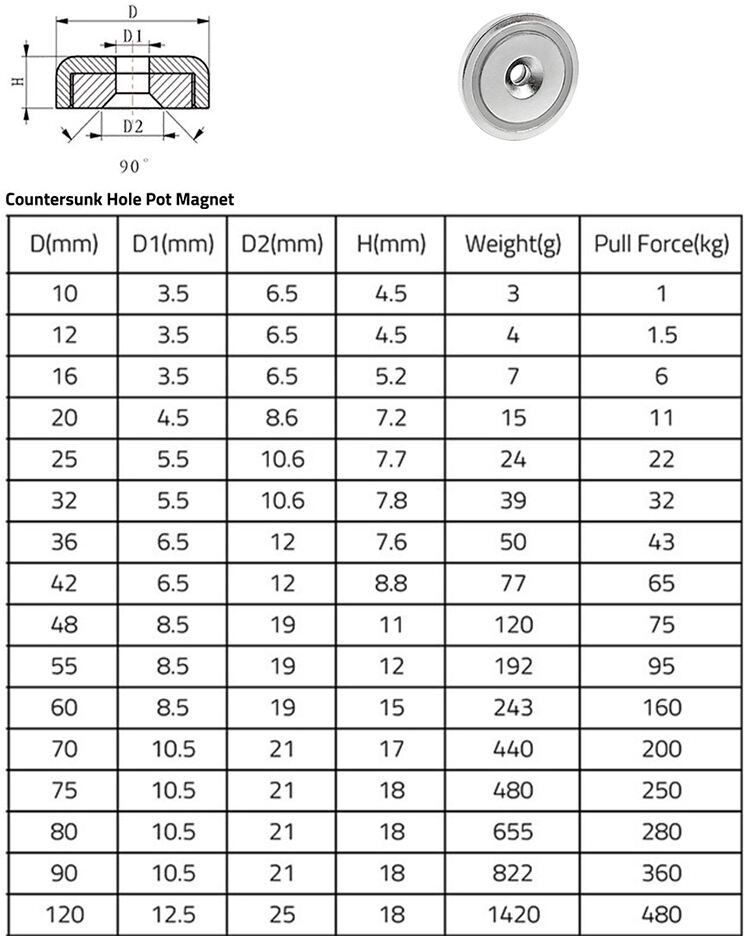

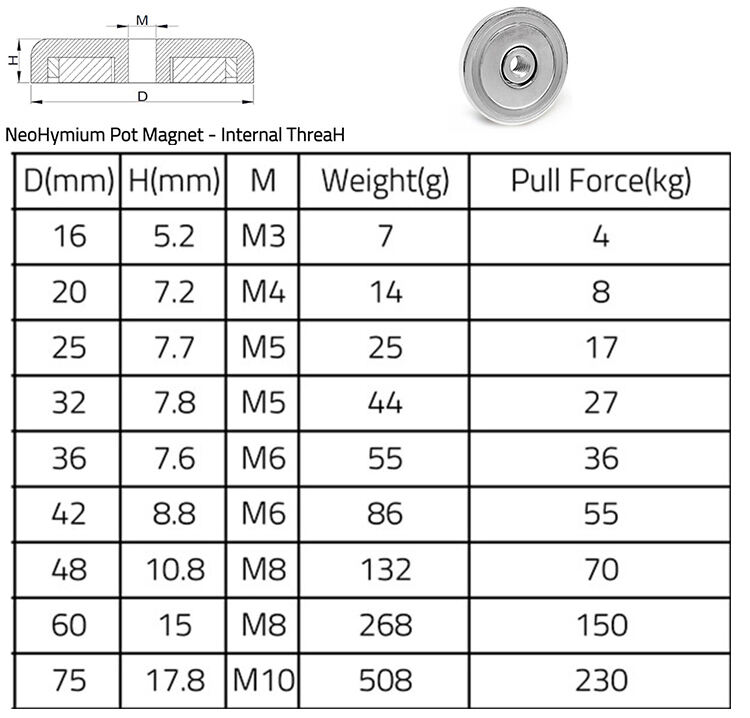

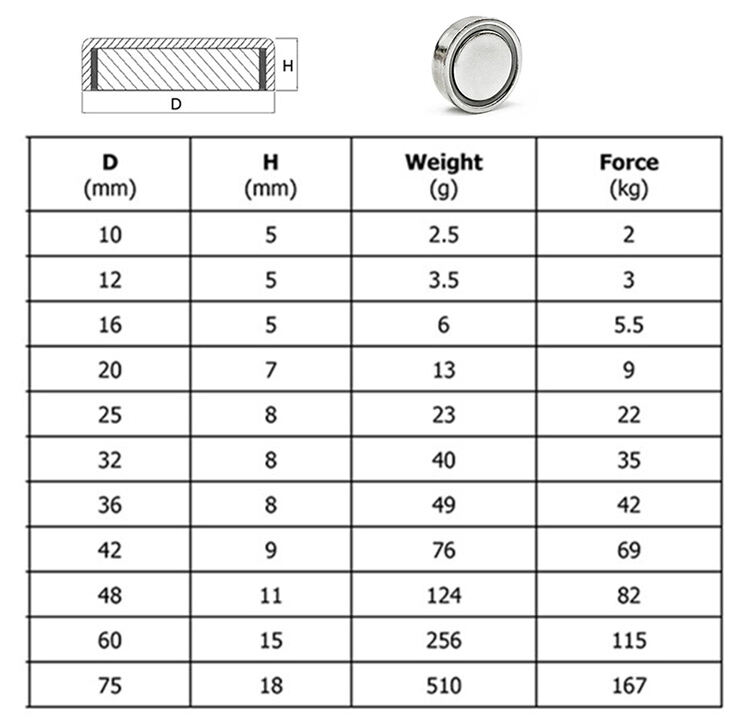

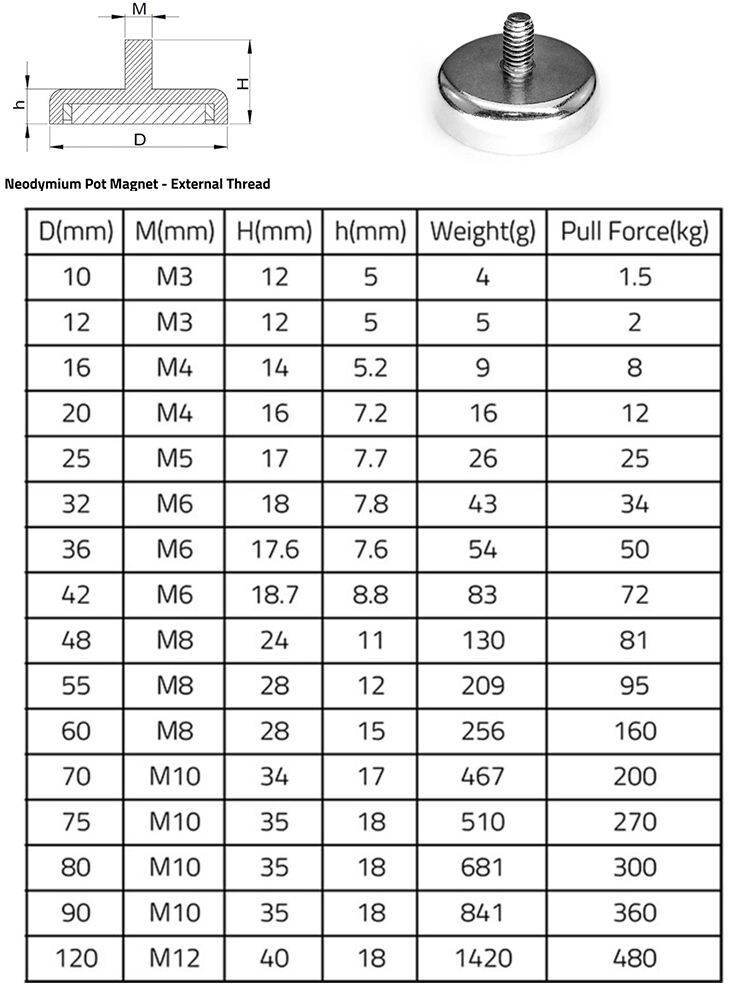

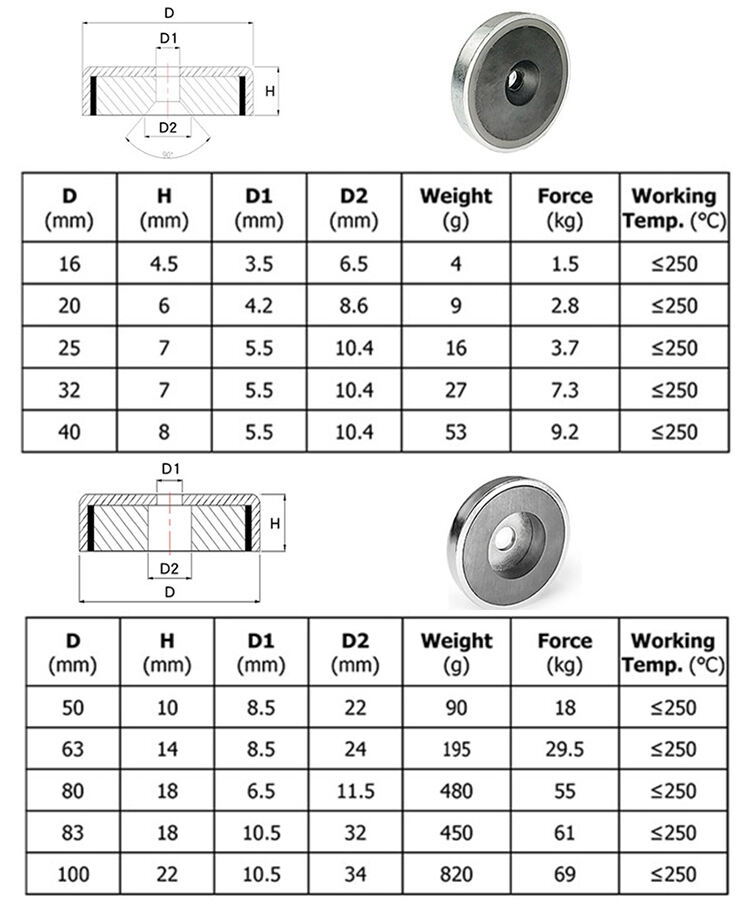

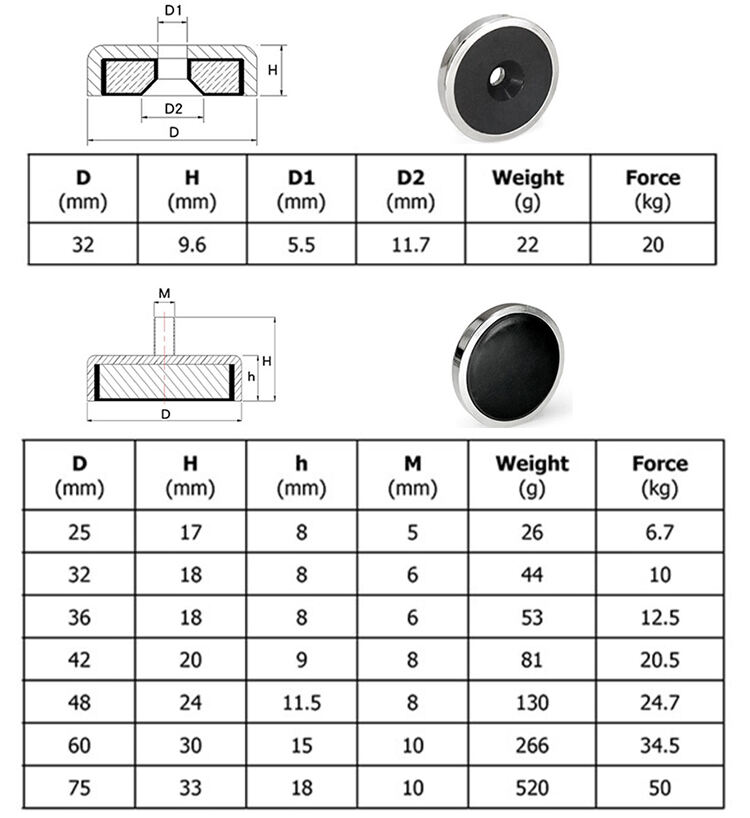

Neodymium Pot magnet

Item Name |

Round Base Pot Magnet with Countersunk Hole |

||||||

Material |

Neodymium Iron Boron |

||||||

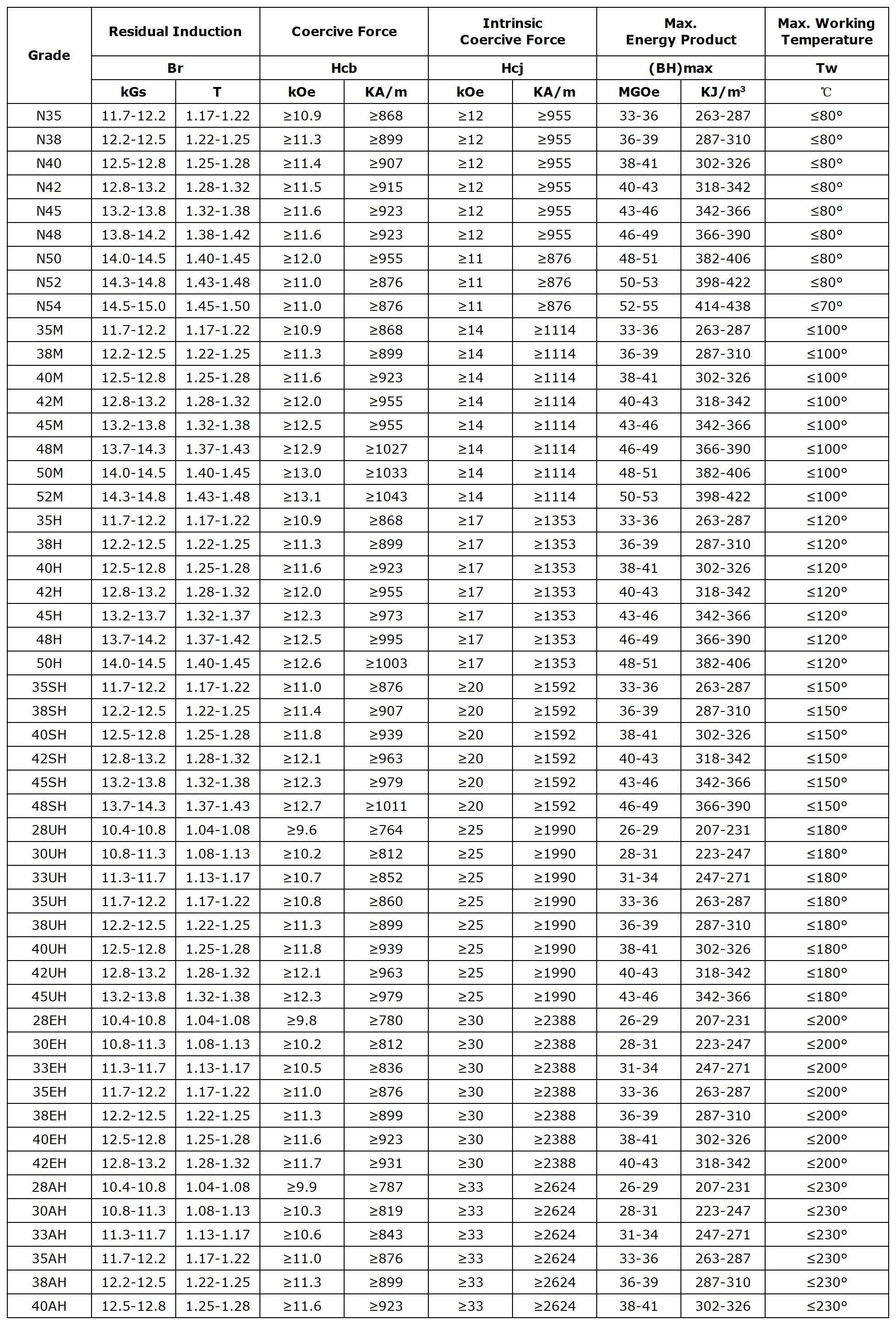

Grade |

Custom made N28 to N54 - NM-EH |

||||||

Size |

Customers' Request |

||||||

Coating |

Nickel-plated (Ni-Cu-Ni-Au), Zn, Expoy, Sliver, others |

||||||

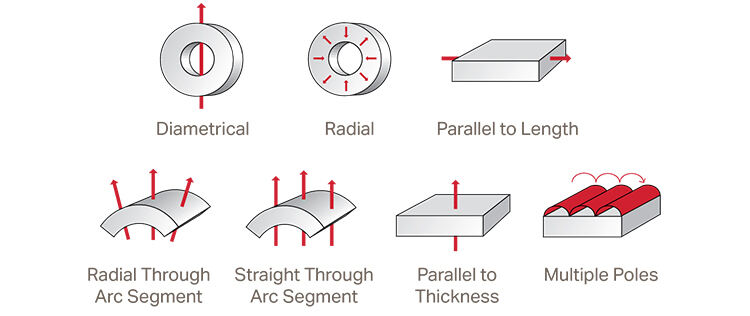

Magnetization |

Thickness, Axial(Other Magnetism direction Contact us) |

||||||

Sample Time |

1-5 Days |

||||||

Leading Time |

8-25 days |

||||||

A: Yes, the samples testing should be necessary for first time, we would like cooperate for samples. If it's regular magnets and we have stock, we would like supply free samples for customers, if need new production, we will quote samples fee and we can accept T/T, Paypal, Western Union, Alibaba trade assurance for payment. We will send the sample to you by DHL express

Q: What magnet materials are available

A: There are many different magnet materials available, which we are able to provide. These include neodymium, samarium cobalt, alnico, ferrite, bonded neodymium, bonded samarium cobalt, bonded ferrite, injection molded neodymium, injection molded samarium cobalt, rubber stripping, and FeCrCu. If there is another material you wish to procure, please contact us

Q:Can you supply custom magnets

A: Yes, we have the capability to produce magnets to your specification in NdFeB, SmCo, AlNiCo, Ferrite, and rubberized magnet materials. You can contact us for more details

Q:Do you have a minimum purchase order

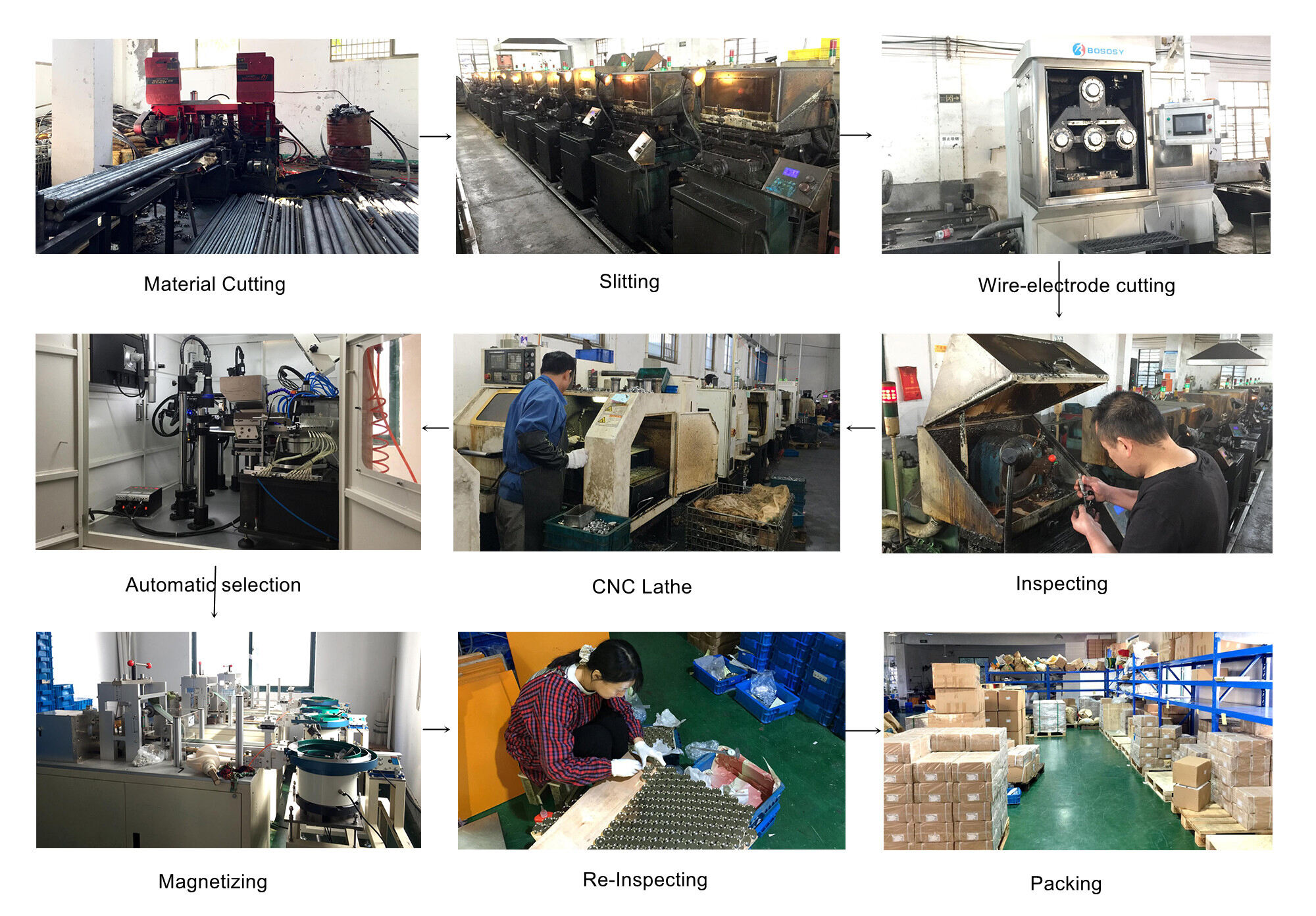

A: The manufacturing of magnets is a complex process, please check our production flow for more information. As considering the production time and cost, we suggest the batch order value should be more than US$3000 per time; Of course, if less than US$3000, we also would like quote our offer for your kind consideration, so we have no strict MOQ

Q: How many days does it take to ship my order

A: In generally, the sintering NdFeB and SmCo magnet production time is 15-25days, cast AlNiCo will take 25-30days, the magnetic assemblies will be about 30-40 days for your reference, the exact time need to be checked before the order

Q:What elements affect the magnet price

A:

1. Shape and size : cylinder (DxH), cuboids(LxWxH), cubes, ring(ODxIDxH) belong to regular shape, arc magnets are popular used in motors or generators, before quotation and batch production, we have to confirm the technical drawing and samples, other irregular shape magnets are also can be made according to request

2: Grade (Magnetic Property)3: Plating(Coating)

4:Magnetizing Orientation

5:Quantity