Strong Cube Neodymium Magnets

Neodymium magnet

Ketaimag Neodymium (NdFeB) permanent magnet is composed of neodymium, iron, boron and a few transition metals. It has many advantages like high coercive force, high energy, high performance/ cost ratio and can be easily formed into ...

- Overview

- Related Products

Neodymium magnet

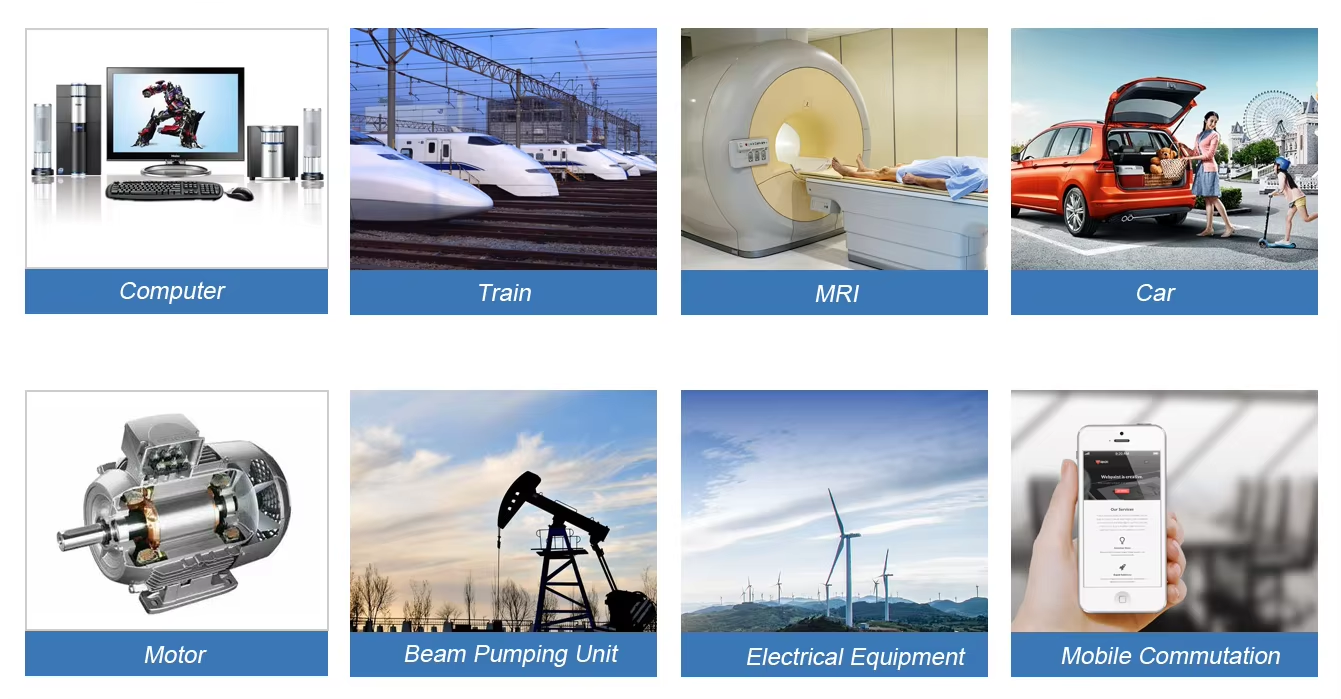

Ketaimag Neodymium (NdFeB) permanent magnet is composed of neodymium, iron, boron and a few transition metals. It has many advantages like high coercive force, high energy, high performance/ cost ratio and can be easily formed into various shapes and widely used in many fields such as aviation, electronics, instruments, meters, DC motors, Liner motors, MRI, medical and health products.

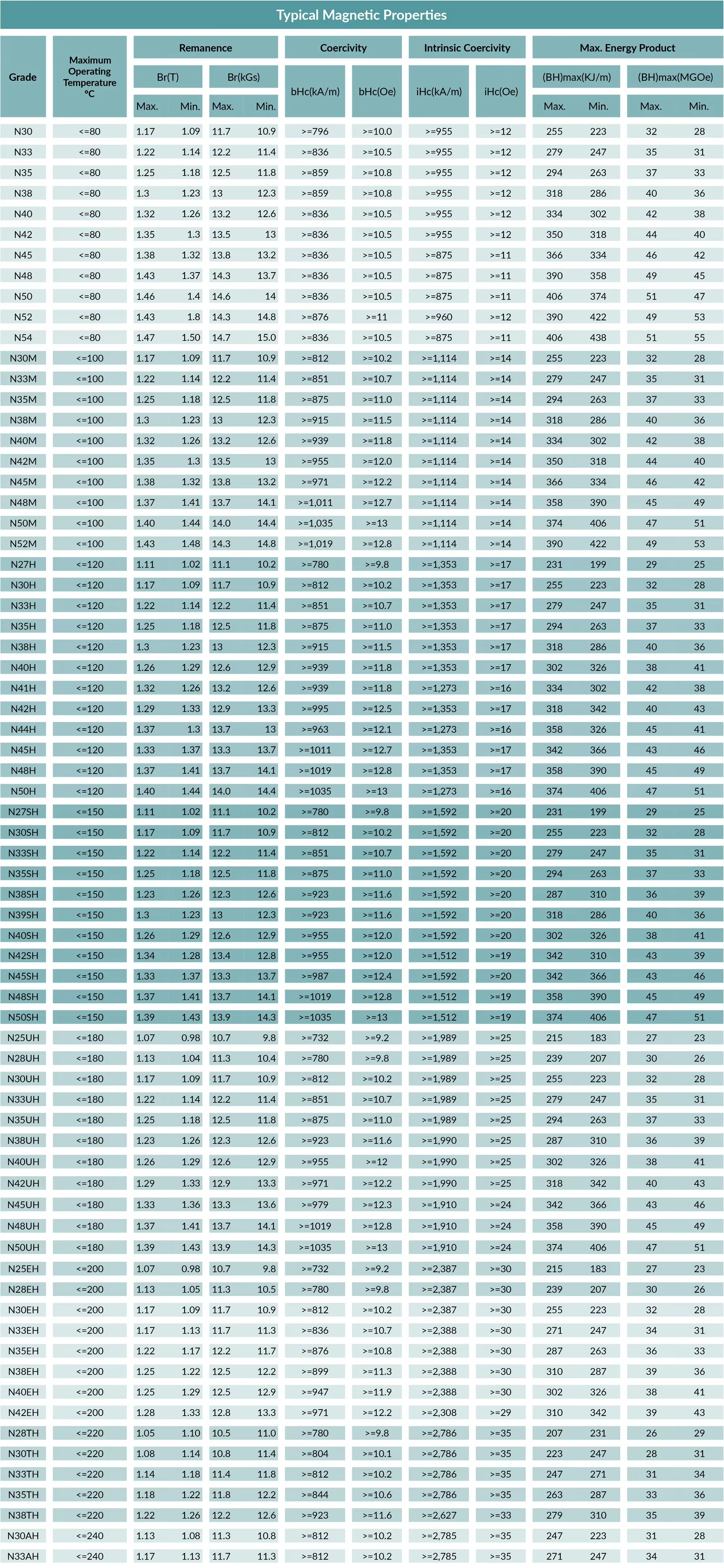

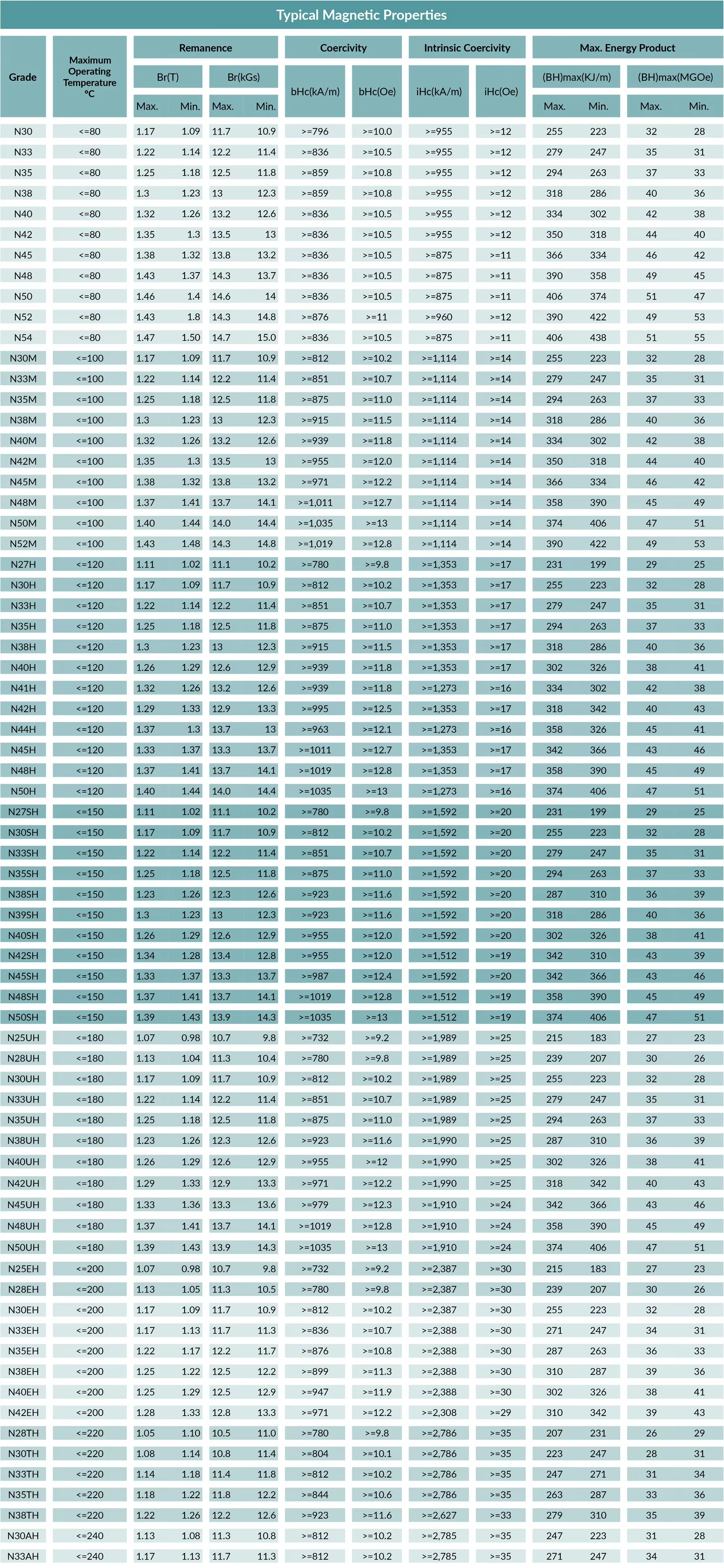

• Grades: N35--N52, N35M--N50M, N35H--N48H, N35SH--N45SH, N28UH--N42UH, N28EH--N40EH

• Coating: Ni-Cu-Ni, Black Nickel, Zn, Sn, Au,Ag, Black Epoxy, Phosphated for All Neodymium Magnet

Demagnetization curves

We list the performance of highest grades with different series when demagnetization.

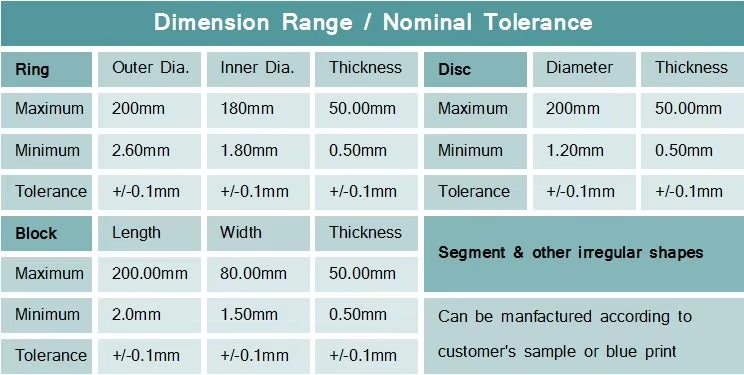

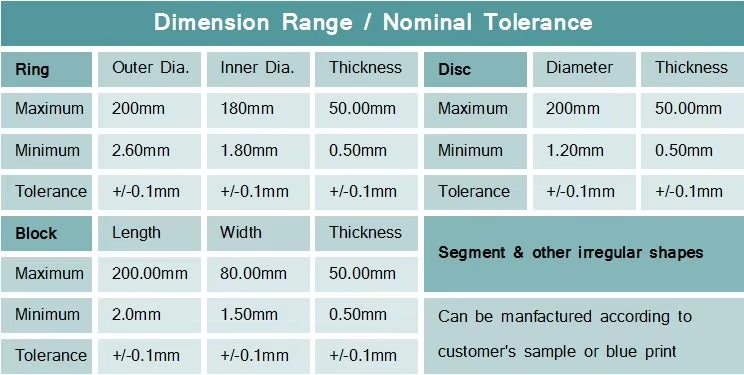

Sizes & Tolerances

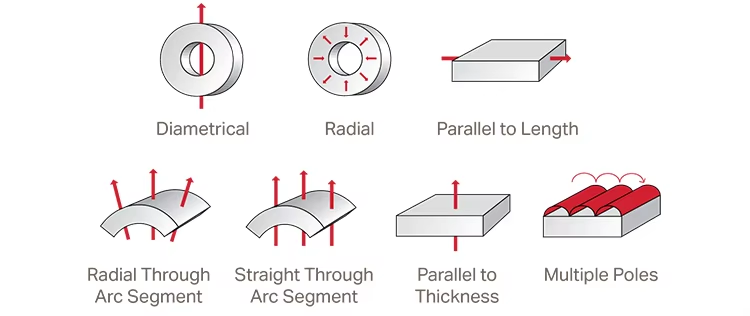

We can produce different shapes, like disc, cylinder, ring, arc segment and custom complicate shapes, a wide range of sizes are possible with a few limits.

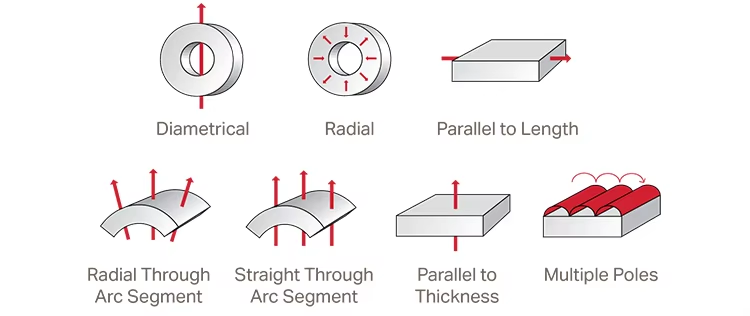

According to customized request, neodymium magnet can make to different shape/different size. Neodymium magnets or NdFeB disc magnets are round coin-shaped Neodymium magnets of varying diameter and thickness.

Generally the NdFeB/Neodymium disc magnets are axially and diametrically magnetized. The axially neodymium disc magnet is means one circular flat face is a North pole, the other circular flat face is a South pole with the distance between the flat faces (the disc thickness) being the distance between the poles (the magnet is magnetized along the central axis of the Neodymium disc magnet). Almost all our NdFeB/Neodymium disc magnets are supplied as axially magnetized NdFeB magnets.

According to customized request, neodymium magnet can make to different shape/different size. Neodymium magnets or NdFeB disc magnets are round coin-shaped Neodymium magnets of varying diameter and thickness.

Generally the NdFeB/Neodymium disc magnets are axially and diametrically magnetized. The axially neodymium disc magnet is means one circular flat face is a North pole, the other circular flat face is a South pole with the distance between the flat faces (the disc thickness) being the distance between the poles (the magnet is magnetized along the central axis of the Neodymium disc magnet). Almost all our NdFeB/Neodymium disc magnets are supplied as axially magnetized NdFeB magnets.

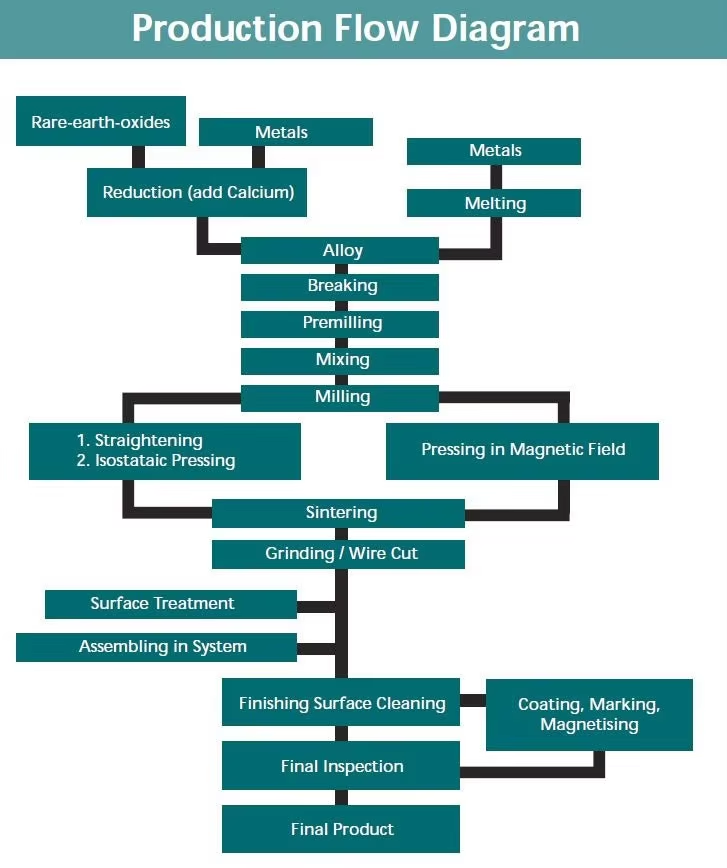

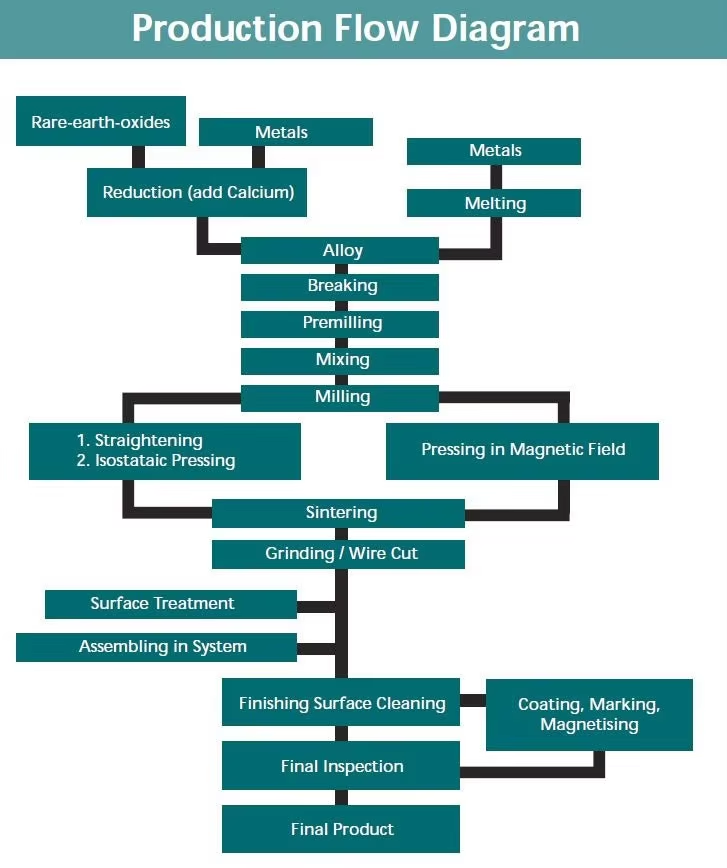

Manufacturing method

Neodymium magnets are made by a sophisticated process using very advanced metallurgical methods, the main process are: Rare earth raw materials - Quick curing - Strip casting - Hydrogen decrepitation - Milling - Pressing - Sintering - BH curve testing - Machining - Plating - Magnetizing - Packaging.

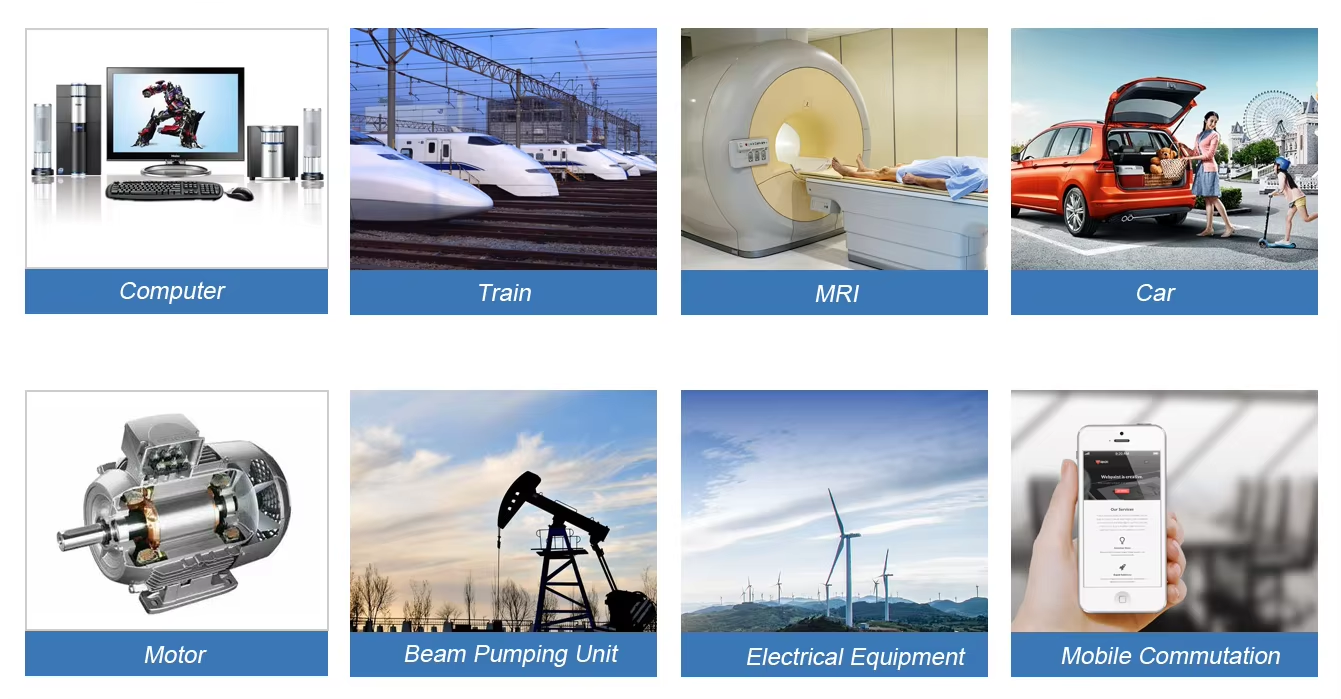

The sintered neodymium-iron-boron (NdFeB) permanent magnet is widely used in permanent magnet servo motor, permanent magnet elevator tractor, wind driven generator, permanent magnet linear motor, permanent magnet step motor, permanent magnet micromotor,permanent magnet oil field motor, permanent magnet transducer, permanent magnet loudspeaker, electronic component, medical equipment and so on.

The sintered neodymium-iron-boron (NdFeB) permanent magnet is widely used in permanent magnet servo motor, permanent magnet elevator tractor, wind driven generator, permanent magnet linear motor, permanent magnet step motor, permanent magnet micromotor,permanent magnet oil field motor, permanent magnet transducer, permanent magnet loudspeaker, electronic component, medical equipment and so on.

Ketaimag Neodymium (NdFeB) permanent magnet is composed of neodymium, iron, boron and a few transition metals. It has many advantages like high coercive force, high energy, high performance/ cost ratio and can be easily formed into various shapes and widely used in many fields such as aviation, electronics, instruments, meters, DC motors, Liner motors, MRI, medical and health products.

• Grades: N35--N52, N35M--N50M, N35H--N48H, N35SH--N45SH, N28UH--N42UH, N28EH--N40EH

• Coating: Ni-Cu-Ni, Black Nickel, Zn, Sn, Au,Ag, Black Epoxy, Phosphated for All Neodymium Magnet

Demagnetization curves

We list the performance of highest grades with different series when demagnetization.

Sizes & Tolerances

We can produce different shapes, like disc, cylinder, ring, arc segment and custom complicate shapes, a wide range of sizes are possible with a few limits.

According to customized request, neodymium magnet can make to different shape/different size. Neodymium magnets or NdFeB disc magnets are round coin-shaped Neodymium magnets of varying diameter and thickness.

Generally the NdFeB/Neodymium disc magnets are axially and diametrically magnetized. The axially neodymium disc magnet is means one circular flat face is a North pole, the other circular flat face is a South pole with the distance between the flat faces (the disc thickness) being the distance between the poles (the magnet is magnetized along the central axis of the Neodymium disc magnet). Almost all our NdFeB/Neodymium disc magnets are supplied as axially magnetized NdFeB magnets.

Manufacturing method

Neodymium magnets are made by a sophisticated process using very advanced metallurgical methods, the main process are: Rare earth raw materials - Quick curing - Strip casting - Hydrogen decrepitation - Milling - Pressing - Sintering - BH curve testing - Machining - Plating - Magnetizing - Packaging.

The sintered neodymium-iron-boron (NdFeB) permanent magnet is widely used in permanent magnet servo motor, permanent magnet elevator tractor, wind driven generator, permanent magnet linear motor, permanent magnet step motor, permanent magnet micromotor,permanent magnet oil field motor, permanent magnet transducer, permanent magnet loudspeaker, electronic component, medical equipment and so on.